Proper maintenance of plastic crushers is critical for safety, efficiency, and longevity. Follow this structured maintenance protocol to minimize downtime and repair costs:

1. Daily Maintenance

Task | Procedure |

Visual Inspection | Check for loose bolts, cracks in housing, or damaged safety guards. |

Hopper/Chamber Cleanout | Remove plastic residues with brushes/air guns (prevents overheating). |

Screen/Grate Clearing | Unclog holes; inspect for wear (>10% hole enlargement = replace). |

Lubrication Spot-Check | Verify grease levels in bearings; listen for grinding noises during operation. |

Dust Management | Vacuum dust from motors, vents, and electrical panels (prevents fires). |

2. Weekly Maintenance

Component | Action |

Blades/Knives | Inspect edges for chips/dulling. Rotate or flip blades to distribute wear evenly. |

Bearings | Replenish high-temp grease (e.g., lithium complex). Check temperature: >70°C (158°F) indicates failure. |

Belts/Chains | Adjust tension; misalignment >1mm/m causes premature wear. |

Drive Motor | Clean cooling fins; check amperage draw (overload = 10%+ above rated). |

Hydraulic Systems | Check fluid levels, leaks, and hose integrity (if applicable). |

3. Monthly/Quarterly Maintenance

Task | Key Steps |

Blade Sharpening/Replacement | Sharpen when edge radius >0.2mm. Replace if cracks/chips >3mm deep. Torque bolts to OEM specs (e.g., 90-110 Nm). |

Bearing Replacement | Replace if vibration exceeds 4.5 mm/s RMS. Use sealed bearings with air purge ports for dusty environments. |

Rotor Alignment | Verify rotor balance (misalignment >0.05mm causes vibration). Check shaft runout with dial indicator. |

Electrical Testing | Tighten terminals; test overload relays, contactors, and emergency stops. |

Screen/Grate Replacement | Replace if holes are distorted or cracked. Match hole size to target plastic particle size. |

4. Annual Overhaul

Disassemble crusher fully.

Inspect/replace seals, bushings, and wear plates.

Rebuild rotor assembly (dynamic balancing required).

Rewind/replace motor if insulation resistance <1 MΩ.

Calibrate sensors (temperature, vibration, overload).

5. Critical Best Practices

Safety First

Always LOCKOUT/TAGOUT before maintenance.

Wear cut-resistant gloves and eye protection when handling blades.

Contamination Control:

Use magnetic separators or metal detectors to stop ferrous debris.

Never process PVC (releases hydrochloric acid) or wet/organic materials.

Blade Care:

Store spare blades coated in anti-corrosion oil.

Use good sharpening wheels for sharpening blades.

Moisture Management:

Install desiccant breathers on bearing housings.

Use compressed air (≤0.5 bar) to blow out residual moisture.

6. Troubleshooting Common Issues

Problem | Likely Cause | Fix |

Excessive Vibration | Unbalanced rotor, loose bolts, worn bearings | Rebalance rotor; torque all bolts; replace bearings. |

Overheating Motor | Blocked vents, voltage drop, overloading | Clean cooling paths; check voltage stability; reduce feed rate. |

Jamming | Oversized material, dull blades, caps | Pre-cut large items; sharpen blades; crush bottles with caps attached. |

Reduced Output Size | Worn screens, blade gap too small | Replace screens; adjust blade clearance (0.3–0.5mm for PET, 0.5–1mm for PP caps). |

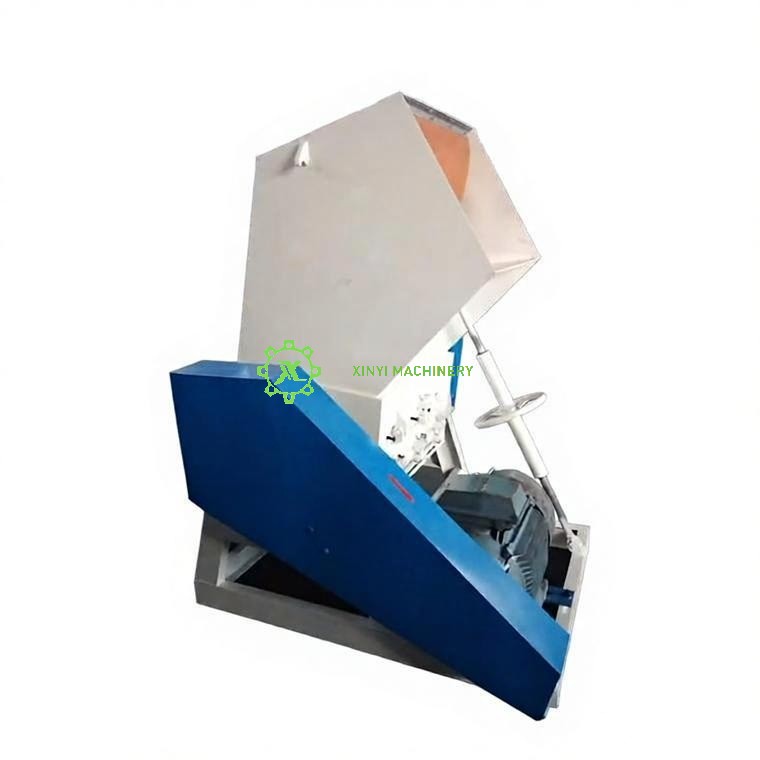

If you can’t solve problems, you can ask the engineer team of Xinyi Machinery.

(Xinyi Machinery is a China leading Manufacturer of all kinds of plastic crushers.)

Final Advice: Keep a maintenance log with dates, parts replaced, and observations.

Adhere to the manufacturer’s maintenance schedule but adjust based on your material mix – caps and reinforced plastics accelerate wear. Partner with your crusher OEM for customized solutions!