Choosing the right crusher screen size is crucial for balancing product fineness, machine throughput, and overall process efficiency. Here's a step-by-step guide based on the principles you provided:

Key Factors for Choosing Screen Size

Desired Final Particle Size (Fineness):

Smaller Holes (e.g., 8mm, 10mm): Produce finer plastic flakes/pellets. Essential if the next process (like extrusion or injection molding) requires small, uniform input material.

Larger Holes (e.g., 14mm, 16mm, 20mm): Produce coarser flakes. Suitable for simpler recycling processes, open-loop recycling, or when further size reduction happens later.

Required Throughput (Output):

Smaller Holes: Restrict material flow, significantly reducing crusher output capacity.

Larger Holes: Allow material to exit faster, maximizing throughput. Choose larger sizes if high volume is critical.

Material Characteristics:

Hardness & Brittleness: Harder, more brittle plastics (e.g., PS, certain ABS) shatter more easily and can often use smaller screens for finer output without drastically reducing throughput.

Flexibility & Toughness: Soft, flexible, or tough plastics (e.g., PE films, PP fibers, rubbery materials) tend to "smear" or resist cutting. Larger screens are often necessary to prevent clogging and maintain flow, even if slightly larger particles are acceptable.

Initial Size/Form: Large, thick items (bottles, containers) generally require larger screens initially than thin films or small sprues/runners.

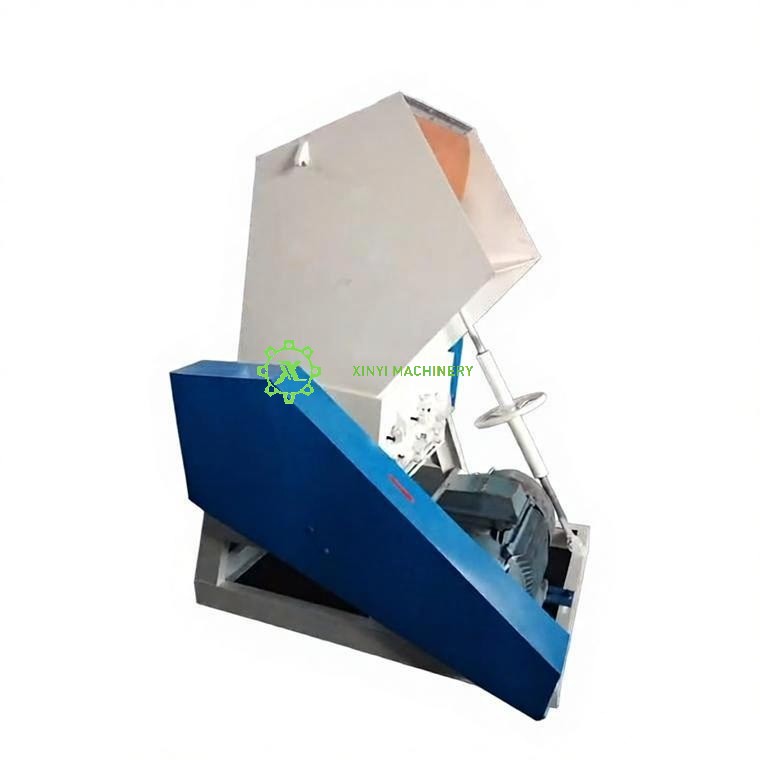

Crusher Power & Capability:

Motor Power: Smaller screens increase resistance and load on the motor. Ensure your crusher has sufficient horsepower to handle the chosen screen size without stalling or overheating, especially for tough materials.

Rotor Design & Knife Sharpness: A robust rotor and sharp knives are essential for efficiently cutting material against a smaller screen.

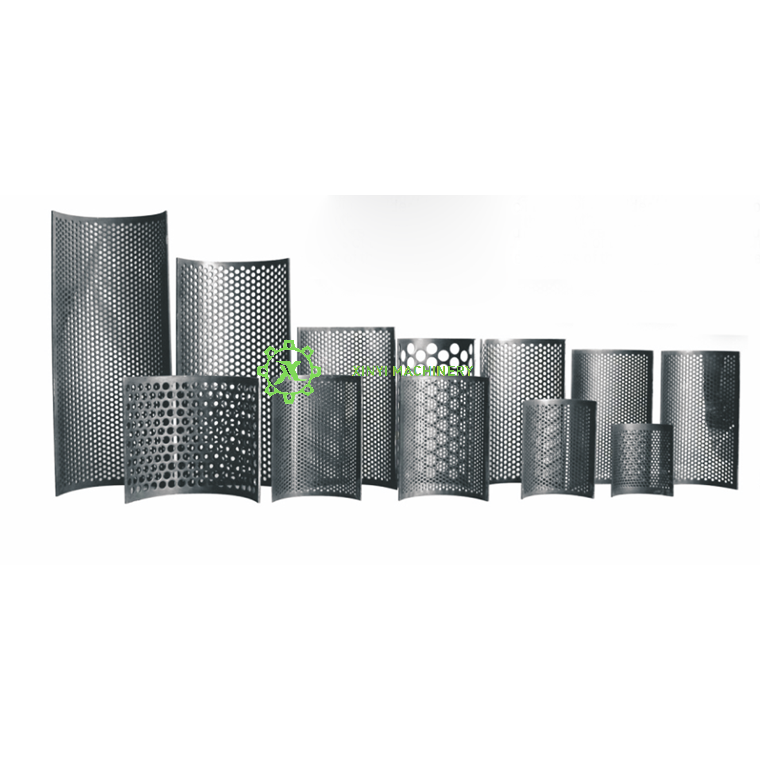

Hole Shape:

Round Holes: Produce more uniformly shaped particles but offer lower open area, reducing throughput for a given hole size.

Square/Rectangular/Slotted Holes: Offer higher open area, allowing significantly more material flow and higher throughput. Particles will be less uniform. Ideal when maximizing output is key and perfect particle shape is less critical.

Downstream Process Requirements:

What size does the extruder, pelletizer, or molding machine require?

Will there be further sorting, washing, or separation? Particle size can affect these steps.

Practical Selection Guide

Identify Downstream Needs: What is the maximum acceptable particle size for your next process? This is your starting point.

Analyze Your Material: Is it hard/brittle or soft/flexible/tough? What are the typical feed sizes?

Define Throughput Goals: How much material per hour must you process?

Consult Crusher Specs: What screen sizes does your crusher manufacturer recommend for your material type and motor power? What is the machine's rated capacity with different screens?

Start with Common Sizes & Test: Use the manufacturer's guidance and the 10mm/12mm/14mm standards as a baseline.

If Fineness is Critical: Start with 10mm (or even 8mm for very fine needs). Monitor throughput and motor load. If throughput is too low or the motor struggles, try 12mm.

If Throughput is Critical: Start with 14mm (or 12mm for a balance). Monitor particle size. If particles are too large for the next step, try 12mm (or 10mm).

For Tough/Flexible Materials: Often require larger screens (12mm, 14mm+) to prevent clogging, even if finer output would be desirable. Square/slotted holes are highly beneficial here.

For Hard/Brittle Materials: Can often achieve finer sizes (8mm, 10mm) with better throughput relative to flexible materials. Round holes work well.

Consider Hole Shape:

Prioritize Round Holes when particle uniformity is paramount and throughput is secondary.

Prioritize Square/Slotted Holes when maximizing throughput is essential and particle shape variation is acceptable.

Iterate & Optimize: Be prepared to test 2-3 screen sizes. The "right" size is the one that reliably produces particles small enough for the next step while maximizing throughput without overloading the crusher.

Consider Customization: If standard sizes (8mm-20mm) don't perfectly meet your needs (e.g., you need slightly finer than 10mm but 8mm chokes the machine), explore custom hole sizes or shapes with your supplier.

Summary Table

Factor | Prefer Smaller Screen (e.g., 8-10mm) | Prefer Larger Screen (e.g., 14-20mm) | Preferred Hole Shape |

Goal: Particle Fineness | High Priority | Low Priority | Round |

Goal: High Throughput | Low Priority | High Priority | Square/Slotted |

Material: Hard/Brittle (PS) | Good Fit | Only if coarse acceptable | Round or Square |

Material: Flexible/Tough (PE Film) | Risk of Clogging, Avoid unless essential | Better Fit | Square/Slotted (Highly Recommended) |

Crusher: Limited Power | Risk of Overload | Safer Choice | Depends on Material |

Downstream: Needs Fine Input | Essential | Not Suitable | Round |

Downstream: Coarse Acceptable | Unnecessary, reduces output | Suitable | Square/Slotted |

In essence: Choose the largest screen size (and often a square/slotted shape) that still produces particles small enough for your next process while allowing your crusher to run at the required throughput without overloading. Testing with your specific material and machine is always the best practice.