As the screen (or sieve) mesh diameter is the primary factor determining the final particle size of the crushed plastic, which directly affects downstream processing efficiency.

The standard hole diameters for plastic crusher screens commonly range from 8mm to 30mm.

Here is a more detailed breakdown of the standard sizes and their typical applications:

Standard Screen Hole Diameters (mm):

· Common Fine Sizes: 6, 8, 10, 12

· Most Common Mid-Range Sizes: 12, 14, 16, 18, 20

· Common Coarse Sizes: 22, 24, 26, 28, 30

· Larger/Custom Sizes: 35, 40, 50+ (for very coarse shredding or specific applications)

Key Information About Crusher Screens:

1. Purpose of the Screen:

The screen acts as a filter. Rotors throw plastic against it, and only particles smaller than the hole diameter can pass through. Larger pieces are retained inside the crushing chamber for further cutting.

2. How to Choose the Right Diameter:

The choice depends entirely on your material and your desired final product.

· For Film, Fibers, Thin Walled Bottles: Smaller screens (8mm, 10mm, 12mm) are used to create fine, uniform flakes.

· For Hard Plastic Lumps, Purgings, Pipes: Larger screens (16mm, 20mm, 24mm) are preferred to reduce energy consumption, prevent overheating, and produce coarse chips suitable for re-granulation.

· For Pre-Shredding before Fine Grinding: Very large screens (26mm, 30mm or bigger) are used in a primary shredder to break down large items like pallets, drums, or pipes into manageable "finger-sized" pieces.

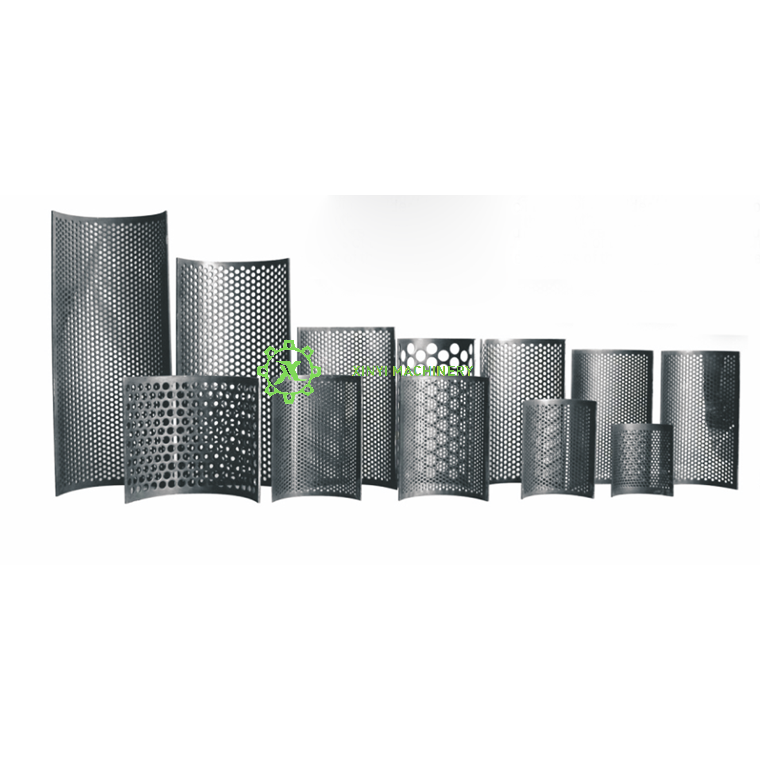

3. Material & Durability:

Screens are typically made from hardened carbon steel or alloy steel to withstand severe abrasion. For highly abrasive materials (e.g., fiberglass-reinforced plastic), wear-resistant liners or specialized screens can be used.

Practical Recommendation:

When consulting with a leading manufacturer like XINYI MACHINERY, you will typically specify:

1. The type and form of plastic (e.g., PET bottles, PP woven bags, PVC pipes).

2. The desired final particle size for your recycling or reprocessing line.

3. The model of your crusher (for correct screen dimensions).

They will then recommend the optimal screen hole diameter. It's also very common for end-users to purchase several screens of different sizes to switch between for processing different materials.

In summary, 8mm to 30mm is the standard range. The correct choice within this range is a critical parameter for optimizing your crushing operation's output and efficiency.